DIIWAAN GELIN OO CUQDAD SARE

Baaxadda Codsiga

Duubitaanka cadaadiska sare ee hal-drive ayaa si gaar ah loogu talagalay in horay loo shiido clinkers-ka sibidhka, wasakhda macdanta, birta birta iyo wixii la mid ah, si loo burburiyo macdanaha macdanaha ah (macdanta birta, manganese, macdanta copper). , macdanta lead-zinc, vanadium ores iyo kuwa kale) iyo in la shiido macdanta aan biraha ahayn (gangues dhuxusha,

feldspar, nephe-line, dolomite, limestone, quartz, iwm) oo budo ah.

Qaab dhismeedka & Mabda'a Shaqada

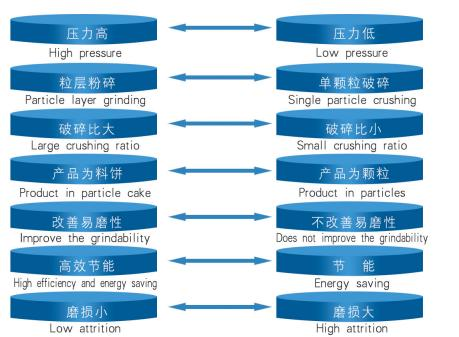

Shaxda Mabaadi'da Shaqada

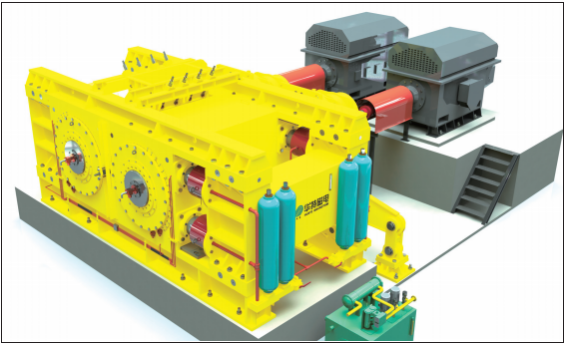

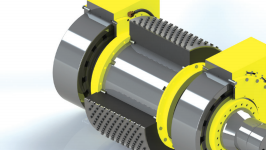

Duubka duubista cadaadiska sare ee singledrive ayaa qaata

mabda'a wax shiida ee wadarta walxaha .

Mid waa liiska taagan, ka kalena waa duub la guuri karo.

Labada duub waxay u wareegaan si liddi ku ah isla xawaare isku mid ah .

Alaabtu waxay ka soo galaan furitaanka quudinta sare,

oo lagu shiido sababtoo ah extrusion cadaadis sare ee farqiga labada duub, oo laga sii daayo xagga hoose.

Qaybta wadista

Hal mooto oo kaliya ayaa loo baahan yahay,

Korontada waxaa lagu kala qaadaa duubka taagan oo loo gudbiyaa duubka dhaqaaqi karo iyada oo loo marayo nidaamka qalabka,

si ay labada duub u wada siman yihiin iyada oo aan lahayn is jiid jiid.

Shaqada waxaa oo dhan loo isticmaalaa extrusion walxaha,

iyo heerka isticmaalka tamarta waa sarreeyaa, kaas oo badbaadiya 45% ee korontada marka loo eego duubista cadaadiska sare ee caadiga ah.

◆ Nidaamka codsashada cadaadiska

Nidaamka cadaadiska farsamada guga ee isku dhafan ayaa ka dhigaya duubka la guuri karo inuu ka fogaado dabacsanaan.

Marka ay birta shisheeye soo gasho.

nidaamka cadaadiska guga ee codsanaya ayaa si toos ah dib u dhigaya oo ka falcelinaya wakhtiga, hubinta in heerka hawlgalku uu sarreeyo ilaa 95%;

halka duuduubka shiididka sare ee dhaqanka uu sameeyo ka fogaansho, saliidda hawooroliga waxay u baahan tahay in lagu sii daayo dhuumaha si loo yareeyo cadaadiska.

Ficilku wuu daahay, kaas oo sababi kara dhaawac ku yimaadda dusha duubka ama cilladda nidaamka hawo-qaadista.

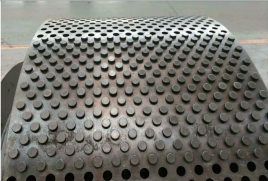

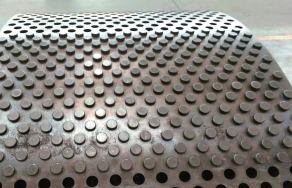

◆ Dusha la rog

Dusha duuban ayaa soo koraysa oo lagu alxanayo wax alxanka u adkaysta, engegnaantuna waxay gaadhi kartaa HRC58-65; cadaadiska si toos ah ayaa loogu hagaajiyaa walxaha,

taas oo aan kaliya ku guulaysan ujeedada shiidi, laakiin sidoo kale waxay ilaalisaa dusha duubka;

duubka la dhaqaajin karo iyo duubka taagani waxay u shaqeeyaan si isku mid ah oo aan is jiid jiid lahayn.

Sidaa darteed, nolosha adeegga ee dusha duubka ayaa aad uga sarreeya kan cadaadiska sare ee caadiga ah ee duudduuban.

Tilmaamaha Farsamada ee ugu Muhiimsan

◆ Hufnaanta Shaqada Sare. Marka la barbardhigo qalabka dhaqameed ee burburinta, awoodda wax-qabadku waxay kordhisaa 40 - 50% .

Awoodda farsamaynta ee PGM1040 waxay gaari kartaa agagaarka 50 - 100 t / h, oo leh 90kw oo keliya.

◆ Isticmaalka Tamarta oo Hooseysa. Sida ku cad dariiqa wadista liiska, waxay u baahan tahay hal matoor si uu u wado.

Isticmaalka tamarta aad ayuu u hooseeyaa. Marka la barbar dhigo HPGR-da dhaqameed ee laba-jibbaaran, waxay hoos u dhigi kartaa isticmaalka tamarta 20 ~ 30% .

◆ Tayada u adkaysata xidhashada Wacan . Hal matoor oo keli ah, waxqabadka is-dhexgalka ee labada duub waa mid aad u wanaagsan.

Dusha alxanka adkaysi u leh, duubabku waxay leeyihiin tayo wanaagsan oo adkaysi u leh si fududna waa loo ilaalin karaa.

◆ Heerka Hawlgalka Sare: ≥ 95%. Naqshadaynta sayniska, qalabka waxaa lagu cadaadin karaa kooxda guga cadaadiska sare .

Cadaadiska shaqada si toos ah ayaa loo hagaajin karaa sida ku cad cadaadinta kooxda gu'ga. Ma jirto meel cilladaysan .

◆ Automation sare iyo hagaajin fudud. La'aanteed nidaamka hydraulic, waxaa jira heerka cilladda oo hooseeya

◆ Dusha duuban ayaa soo koraysa iyadoo lagu alxanayo walxo u adkeysaneysa dabaysha, oo leh engegnaan sare iyo iska caabin wanaagsan;

Cadaadiska guga wuxuu ka yimaadaa xoogga falcelinta ee maaddada, cadaadiska mar walba waa mid dheellitiran,

kaas oo aan gaadhin ujeeddada burburinta,

laakiin sidoo kale waxay ilaalisaa dusha duubka; duuduubka dhaqaaqi karo iyo duubka taaganba waa la miidhiyay oo waxaa wada nidaamka gear,

Xawaaruhuna gabi ahaanba waa la wada siman yahay, si looga fogaado is jiid jiidka u dhexeeya shayga iyo dusha duubka.

Sidaa darteed, nolosha adeeggu aad ayay uga badan tahay ta laba-wadista HPGR .

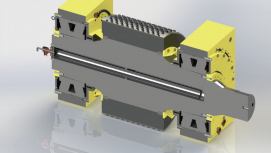

◆ Qaab dhismeed is haysta iyo meel yar oo dabaq ah .

Qiyaasaha Farsamada

| Qaabka | Dhexroor duubmm | Dulqaadwidthmm | M ax .cabirka(Sibidhka, birta, oreslag) mm | Quudinta ugu wanaagsancabbirka(bireedm i n e r a l ,aan bir ahaynmacdanta) mm | Cabbirka wax soo saarka(sibidh)mm | Awoodda socodsiintaT/h | M o rawood Kw | cabbirrada dulucda(L×W×H)mm |

| PGM0850 | φ800 | 500 | 50 | 30 | Kala soocida,4 | 30~40 | 37 | 2760×2465×1362 |

| PGM1040 | φ1000 | 400 | 50 | 30 | Kala soocida,4 | 50~80 | 90 | 4685×4300×2020 |

| PGM1060 | φ1000 | 600 | 50 | 30 | Kala soocida,4 | 70~110 | 110 | 4685×4300×2020 |

| PGM1065 | φ1000 | 650 | 50 | 30 | wax u dhimaya,4 | 100~160 | 200 | 5560×4500×2200 |

| PGM1250 | φ1200 | 500 | 50 | 30 | Kala soocida,4 | 120~180 | 250 | 6485×4700×2485 |

| PGM1465 | φ1400 | 650 | 50 | 30 | Kala soocida,4 | 240~320 | 630 | 9200×6320×3600 |

| PGM1610 | φ1600 | 1000 | 50 | 30 | Kala soocida,4 | 500~650 | 1250 | 10800×8100×4400 |

Isbarbardhigga U Dhaxeya HAL DRIVE HPGR iyo HPGR-ga caadiga ah

HABKA HORUMARKA HORUMARKA KA HOR SHAXDA HAL DRIVE HPGR

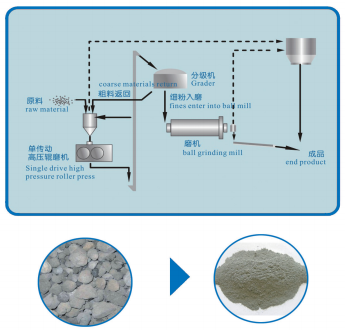

Horay u shiididda sibidhka, birta iyo birta birta " Burburinta badan iyo shiididda yar, ku beddel shiida iyadoo la burburinayo", taas oo ah, horay u shiidi, waxay noqotay tignoolajiyada caadiga ah ee habka wax soo saarka tuubooyinka si loo kordhiyo wax soo saarka loona yareeyo isticmaalka tamarta. . Sida qalabka ugu horumarsan ee hore loo shiiday ee kaydinta tamarta, hal-wadista HPGR waxay burburin kartaa alaabta ilaa -4mm ama -0 .5mm, kuwaas oo 0 .08mm ay ka badan yihiin 30%. Awoodda mashiinka kubbadda la isticmaalo waxaa lagu kordhin karaa 50 ~ 100%, iyo nidaamka isticmaalka awoodda wax lagu shiido waxaa lagu dhimi karaa 15 ~ 30%.

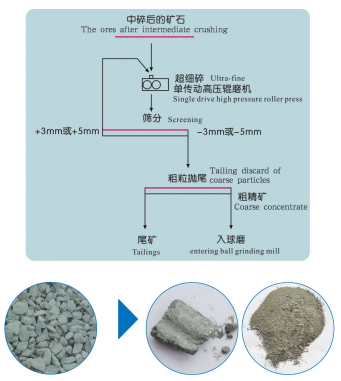

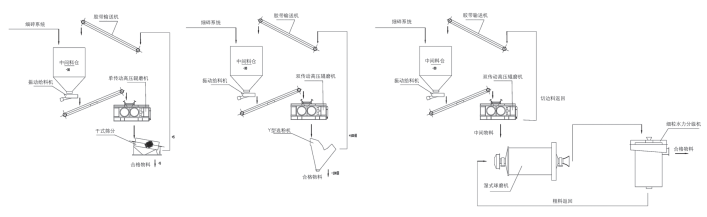

SHAAXDA HABKA HAB-socodka BURBURINTA aadka u aadka u Fiican ee Macdanta Birta leh ee leh hal darawal oo HPGR ah

Burburinta Fiican ee aadka u Fiican ee Macdanta Biraha ah

Marka macdanta ay dhex maraan farqiga u dhexeeya labada duub, waxaa lagu jajabiyaa qaybo yaryar -5 mm ama -3 mm iyo qadar badan oo budo ah oo cadaadis sare leh. Sababtoo ah xoogga isku-xidhka daciifka ah ee is-dhexgalka ka dhexeeya macdanta faa'iidada leh iyo gangue, jabka daalka ama micro-crack iyo walbahaarka gudaha ayaa si sahlan loo abuuraa. Qayb ka mid ah is-dhexgalka ayaa si buuxda u kala go'i doona.

Sababtoo ah maadada sare ee budada ganaaxa ah ee laga sii daayo HPGR iyo xaqiiqda ah in macdanta lagu jajabiyo dusha sare ee kala-baxa, marka la barbar dhigo burburinta caadiga ah, saamiga isdhexgalka ee alaabta la jajabiyey waa la dhimay, iyo dabada ayaa iska tuura ef- cudurku wuu fiican yahay.

Labada darajo dhuuban iyo waxsoosaarka qashinka ayaa si weyn loo hagaajiyay .

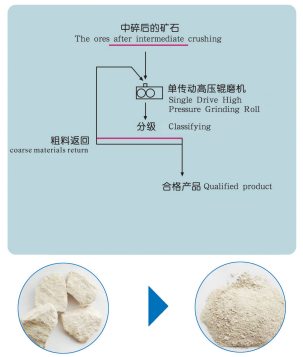

SHAXDA HABKA HABKA CODSIGA EE MACDAANKA AAN BIXIN AHAYN EE HAL DRIVE HPGR

Shiididda Macdanta Aan-Birta Ahayn

Marka la barbar dhigo qalabka wax lagu shiido ee dhaqameed, hal-drive HPGR wuxuu leeyahay faa'iidooyinka awoodda hal mashiin ee weyn, isticmaalka tamarta yar, xirashada yar iyo wasakhowga birta oo yar; ganaaxa alaabta waxaa lagu xakameyn karaa laga bilaabo 20 mesh ilaa 120 mesh, kaas oo bedeli kara kubbadda kubbadda oo abuuri kara hab cusub oo wax lagu shiido.

LUQADDA TAXANAHA CADAADADA SARE EE HPGM

Mabda'a Shaqada

HPGM taxane ah oo duudduuban cadaadiska sare waa nooc cusub oo tamarta-badbaadinta qalabka wax lagu shiida loogu talagalay by mabda'a of cadaadis-sare qalabka shiididda. Waxay ka kooban tahay laba duub oo isku duuban oo si isku mid ah ugu wareegaya xawaare hooseeya . Midi waa duubitaan taagan midna waa duub guurto, oo labaduba ay wataan matoor awood sare leh. Alaabta si siman ayaa looga quudiyaa xagga sare ee labada duub, waxaana si joogto ah loogu qaadaa farqiga duubka iyadoo duubka tuujinayo. Ka dib markii lagu soo rogay cadaadis sare oo ah 50-300 MPa, keega walxaha cufan ayaa laga soo saaraa mashiinka. Keega walxaha la sii daayay, marka lagu daro qayb gaar ah oo ka mid ah alaabooyinka u qalma, qaabka gudaha ee qaybaha alaabta aan u qalmin waxaa ka buuxsamay tiro badan oo dildilaaca micro ah oo ay ugu wacan tahay cadaadiska sare ee cadaadiska, si awoodda wax-ku-oolnimada walxaha ay tahay si weyn ayaa loo hagaajiyay . Qalabka ka dib markii la soo saaro, ka dib kala-baxa, kala-soocidda iyo baarista, alaabta ganaaxa ee ka yar 0.8 mm waxay gaari kartaa ilaa 30%, iyo walxaha ka yar 5 mm waxay gaari karaan in ka badan 80%. Sidaa darteed, habka shiida ee dheeraadka ah, isticmaalka tamarta shiidadu waa la dhimi karaa ilaa xad weyn, si awoodda wax soo saarka ee qalabka wax lagu shiidi karo si buuxda loo hawlgelin karo, guud ahaan awoodda nidaamka kubadda cagta waxaa lagu kordhin karaa 20% ~ 50 %, iyo wadarta isticmaalka tamarta waxaa lagu dhimi karaa 30% ~ 50% ama ka badan.

Goobaha Codsiga

Waxaa jira noocyo badan oo kheyraadka birta ah ee Shiinaha, laakiin tayada noocyada badan ee macdanta ayaa ah kuwa liita, kala duwan iyo ganaax. Si loo xalliyo dhibaatooyinka muuqda ee dhinacyada dhaqaalaha, farsamada iyo ilaalinta deegaanka ee horumarinta macdanta, shirkadaha macdanta birta ee gudaha ayaa si firfircoon u soo bandhigaya, dheefshiidka iyo nuugista qalab cusub oo macdan qodis ah oo hufan. Asalka suuqan, HPGR waa qalab wax lagu shiidi karo oo tayo sare leh marka hore la baadhay oo la soo bandhigay, oo bilaabay in loo isticmaalo shirkadaha macdanta birta ee gudaha. Sidoo kale waa qalabka wax-soo-saarka miinada ee ay aadka uga walaacsan yihiin warshadaha macdan qodista . Waxaa la dhihi karaa HPGR waxaa si weyn loogu isticmaalaa biraha gudaha. HPGR ayaa si weyn loogu isticmaalay gudaha iyo dibaddaba shiida warshadaha sibidhka, granulation ee warshadaha kiimikada, iyo shiida ganaaxa pellet si loo kordhiyo aagga dusha gaarka ah. Waxaa loo isticmaalaa burburinta macdanta birta si loo gaaro ujeedooyin kala duwan sida fududaynta habka burburinta, jajabinta badan iyo shiididda yar, hagaajinta wax soo saarka nidaamka, hagaajinta saamaynta shiida ama tilmaamayaasha kala soocida.

Baaxadda Codsiga Waxqabadka

1. Dhexdhexaad, ganaax iyo ultrafine shiidi alaabta badan .

2. Warshadaha warshadaynta macdanta, waxaa la dhigi karaa ka hor inta aan kubbadda lagu shubin, sida qalab horay loo shiiday, ama ka samaysan habka wax lagu shiido oo la isku daray oo leh kubbadda kubbadda.

3. Warshadaha pellet oksaydhaysan, waxay bedeli karaan warshadda qoyan ee caadiga ah.

4.In qalabka dhismaha, alaabta refractory iyo warshadaha kale, ayaa si guul leh codsatay in clinker sibidhka, nuuradda, bauxite iyo shiidi kale.

Faa'iidooyinka Alaabta

1. Naqshadaynta cadaadiska joogtada ah waxay hubisaa cadaadiska siman ee u dhexeeya duubista waxayna hubisaa saamaynta burburinta.

2. Sixitaan toos ah oo toos ah, waxay si dhakhso ah u hagaajin kartaa farqiga duubista si loo hubiyo jilicsanaanta qalabka.

3. Nidaamka kala soocida cidhifku wuxuu yareeyaa saameynta cidhifyada saamaynta burburinta.

4. Kaarbiid sibidh leh, adeeg nolol dheer, dayactir fudud, iyo mid la bedeli karo.

5. Baanka valve wuxuu qaataa qaybaha dibedda laga keeno, iyo nidaamka hydraulic wuxuu leeyahay naqshad macquul ah iyo kalsooni wanaagsan.

Qaab dhismeedka HPGR

| Qaabka | Dhexroor duubmm | Ballaca duubka mm | Isku soo wada duubookartida | Cabbirka quudinta | Miisaanka mashiinkat | Awood la rakibay |

| HPGM0630 | 600 | 300 | 25-40 | 10-30 | 6 | 74 |

| HPGM0850 | 800 | 500 | 50-110 | 20-35 | 25 | 150-220 |

| HPGM1050 | 1000 | 500 | 90-200 | 20-35 | 52 | 260-400 |

| HPGM1250 | 1200 | 500 | 170-300 | 20-35 | 75 | 500-640 |

| HPGM1260 | 1200 | 600 | 200-400 | 20-35 | 78 | 600-800 |

| HPGM1450 | 1400 | 500 | 200-400 | 30-40 | 168 | 600-800 |

| HPGM1480 | 1400 | 800 | 270-630 | 30-40 | 172 | 800-1260 |

| HPGM16100 | 1600 | 1000 | 470-1000 | 30-50 | 220 | 1400-2000 |

| HPGM16120 | 1600 | 1200 | 570-1120 | 30-50 | 230 | 1600-2240 |

| HPGM16140 | 1600 | 1400 | 700-1250 | 30-50 | 240 | 2000-2500 |

| HPGM18100 | 1800 | 1000 | 540-1120 | 30-60 | 225 | 1600-2240 |

| HPGM18160 | 1800 | 1600 | 840-1600 | 30-60 | 320 | 2500-3200 |

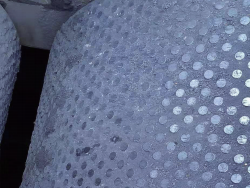

Tignoolajiyada dusha sare ee duudduuban nooca cusub

Waxay qabataa ulaha daawaha adag oo tayo sare leh oo leh adayg sare iyo iska caabin xidhid wanaagsan.

Habaynta stud waxa loogu talagalay jilitaanka kombiyuutarka,

habayntuna waa mid macquul ah, kaas oo samayn kara lakab shay oo isku mid ah inta u dhaxaysa birta, si wax ku ool ah u ilaalinaysa birta iyo dushooda duubka,

iyo hagaajinta nolosha ser ku xigeenka ee duubista tuujin. Kararrada waxaa lagu rakibay dhejisyo gaar ah oo dibadda laga keeno si ay u fududaato beddelka.

Farsamada kala soocida ee duurka duubka iyo usheeda dhexe

Jidhka ugu muhiimsan ee duubista tuujintu waxay ka samaysan tahay bir been abuur ah oo tayo sare leh, iyo duurka duudduuban waxaa lagu sameeyay bir tayo sare leh. Dhuxusha ugu weyn iyo duubabka ayaa ka samaysan waxyaabo kala duwan, taas oo hagaajinaysa adkaanta qulqulka weyn iyo qallafsanaanta duurka duubista. Nolosha adeegga ee kaynta usheeda ayaa si weyn loo hagaajiyay. Beddelka duurka duubka ayaa ku habboon .

Farsamaynta deg-degga ah ee kor u qaadida iyo dejinta tikniyoolajiyadda dhejiska ah ee tayada sare leh ayaa la qaatay taangiga saliidda cadaadiska sare ayaa la sameeyay. Xadhkaha si fudud ayaa loo dejin karaa iyada oo loo marayo bamka saliidda ee cadaadiska sarreeya, si weyn u yareynaya dhibka beddelka xajinta iyo hagaajinta waxtarka dayactirka

Tiknooloojiyada xidhitaanka ee isku dhafan ee badan

Shaabadda wax-soo-saarka waxay qabataa noocyo kala duwan oo J-nooc ah oo lagu daray V-nooca iyo shaabadihii shaybaadhka, iyo tignoolajiyada isku-darka ah ee xidhidhku waxay si wax ku ool ah u xaqiijisaa saamaynta xidhidhiyaha.

Socodka Faa'iidada Birta Birta

Dusha duubista ee tayada sare leh ee xidhashada u adkaysta

Ka dib marka alaabta la soo saaro,

lakabka cufan ayaa laga sameeyay dusha duubka si loo ilaaliyo dusha duubka .

Walxaha ceeriin

Keega alaabta