-

HMB Pulse Boorka Uruurinta

Sumadda: Huate

Asal ahaan badeecada: Shiinaha

Qaybaha: Qalabka Kaaliyaha

Codsiga: Waxaa loo isticmaalaa nadiifinta hawada iyadoo laga saarayo boodhka hawada ee hababka warshadaha kala duwan. Waxaa loogu talagalay inay soo jiidato boodhka dusha sare ee qaybaha shaandhada oo ay ku sii dayso gaasta la safeeyey jawiga.

- 1. Ururinta Siigada Waxtarka leh: Isticmaala isku darka hawo macquul ah si uu u yareeyo culayska saaran boodhka qabadiyaha iyo inta jeer ee garaaca wadnaha.

- 2. Shaabadeynta Tayada Sare iyo Isku-ururinta: Tilmaamaha bacaha shaandhaynta leh shaabad gaar ah oo shaabadaysan iyo qaab siman, kor u qaadida waxqabadka xidhitaanka iyo kordhinta nolosha bacda.

- 3. Waxtarka Uruurinta Boodhka SareWaxay bixisaa bacaha shaandhada kala duwan oo ku habboon jawiga shaqada oo leh hufnaan boodh ururin ah oo ka badan 99.9%.

-

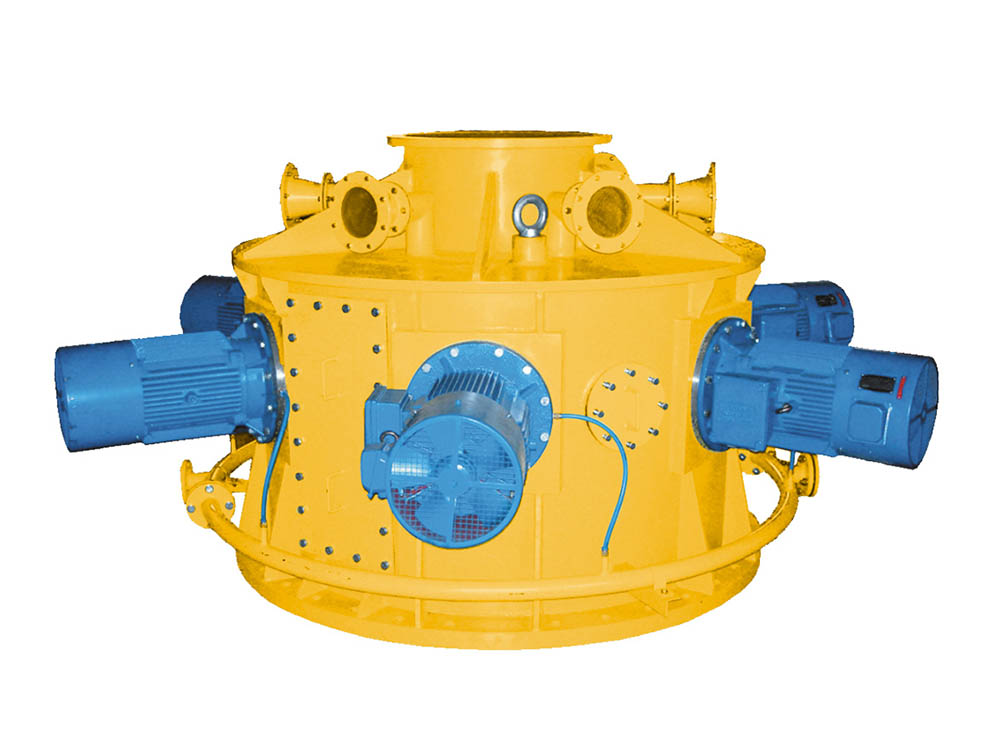

HFW oof-wareenka

Sumadda: Huate

Asal ahaan badeecada: Shiinaha

Qaybaha: Kala saarista

Codsiga: Qalabka kala soocida waxaa si weyn loogu isticmaalaa kiimikooyinka, macdanta (macdanta aan ahayn sida calcium carbonate, kaolin, quartz, talc, mica), metallurgy, abrasives, ceramics, qalabka aan dabka lahayn, daawooyinka, sunta cayayaanka, cuntada, sahayda caafimaadka, iyo warshadaha alaabta cusub.

- 1. granularity la hagaajin karoWaxay u kala saartaa cabbirka alaabta D97: 3 ~ 150 micrometers, oo leh heerar granularity si fudud loo hagaajin karo.

- 2. Waxtarka sare: Waxay ku guulaysataa 60% ~ 90% hufnaanta kala soocida, iyadoo ku xiran walxaha iyo joogteynta walxaha.

- 3. Isticmaale-saaxiibtinimo iyo deegaan-saaxiibtinimo: Nidaamka xakamaynta barnaamijka ee loogu talagalay hawlgal sahlan, wuxuu ku shaqeeyaa cadaadis taban oo leh qiiqa sii daaya ee ka hooseeya 40mg/m³ iyo heerarka qaylada ee ka hooseeya 75dB (A).

-

Kala soocida oofwareenka HF

Sumadda: Huate

Asal ahaan badeecada: Shiinaha

Qaybaha: Kala saarista

Codsiga: Qalabkan kala soocida waxa uu ku haboon yahay beeraha warshadaha u baahan kala soocida qayb sax ah, gaar ahaan codsiyada halkaas oo xakamaynta adag ee cabbirka qayb muhiim ah.

- 1. Soocidda Saxnaanta Sare: Qaab dhismeedka gaarka ah ee loo qaabeeyey iyo saxnaanta kala-saaridda sare waxay si adag u xannibi kartaa qaybo waaweyn, hubinta tayada alaabta.

- 2. toosin: Xawaaraha rotary ee kala soocida taayirrada iyo mugga hawada gelitaanka hawada ayaa la hagaajin karaa si loo helo badeecada la rabo, iyadoo la siinayo dabacsanaan si loo buuxiyo shuruudaha wax soo saarka ee kala duwan.

- 3. Waxqabad hufan oo deggan: Naqshadaynta rotor-ka tooska ah ee hal-xawaaraha hooseeya waxay hubisaa goob socodka xasilloon, oo bixisa waxtarka sare iyo waxqabadka adag.

-

Qalab Quartz-qalalan ah oo lagu farsameeyo

Sumadda: Huate

Asal ahaan badeecada: Shiinaha

Qaybaha: Shiidi

Codsiga: Si gaar ah loogu talagalay goobta quartz-samaynta ee warshadaha galaaska.

- 1. Wax-soo-saarka Wasaaq-La'aanta ahDahaarka silica ayaa ka hortagaya wasakhowga birta inta lagu jiro habka wax soo saarka ciidda.

- 2. Waara oo xasiloon: Qaybaha birta daawaha tayada sare leh waxay xaqiijiyaan iska caabbinta xirashada iyo qallafsanaanta ugu yar.

- 3. Waxtarka sare: Lagu qalabeeyay shaashado kala duwan oo qiimeyn ah iyo wax-soo-saar nadiif ah oo hufan oo tayo sare leh.

-

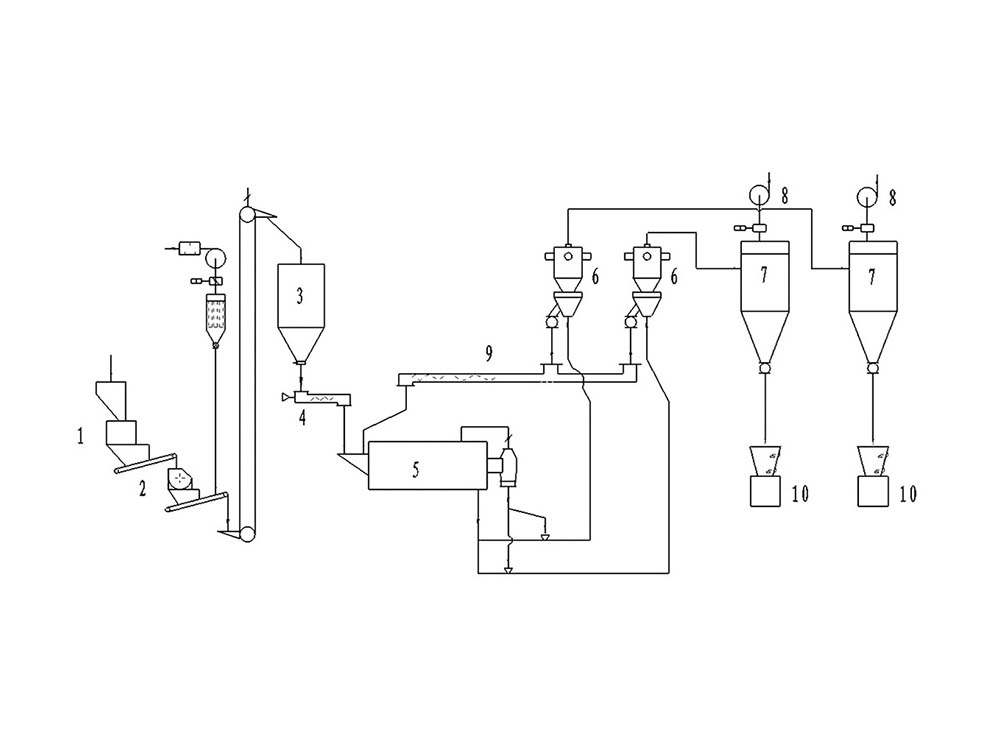

Socodka socodka Quartz ee Khadka Wax soo saarka ciidda

Socodka socodka Quartz ee Khadka Wax soo saarka ciidda

-

Khadka farsamaynta ee Walxaha baytariga

Codsiga:Xariiqda farsamaynta waxaa inta badan loo isticmaalaa kala-saarida burburinta ee alaabta korantada togan iyo taban. Waxa kale oo lagu dabaqi karaa engegnaanta Mosh ee ka hooseeya 4 walxood oo kiimiko ah, cuntooyinka, warshadaha aan macdanta ahayn iyo wixii la mid ah.

-

Taxanaha HSW Horizontal Jet Mill

HSW taxane micronizer hawada jet Mill, oo leh kala soocida duufaanka, boodhka ururiyaha iyo marawaxad qabyo ah si ay u noqdaan nidaam shiidi. Hawo cadaadis leh marka la engejiyo ka dib ayaa si degdeg ah loogu duraa qolka wax lagu shiidi karo iyadoo la duri doono valves. Meelaha isku xirka ee qadarka weyn ee qulqulka hawada cadaadiska sare leh, alaabta quudinta ayaa isku dhacay, la xoqay oo si isdaba joog ah loogu xiiray budada. Alaabta la shiiday waxay galaan qol kala soocida oo leh qulqulka hawada kacsan, iyadoo ay ku hoos jiraan xaalad xoog wax jiidis ah. Marka ay hoos yimaadaan xoogaga centrifugal ee xoogga badan ee giraangiraha turbo-ga wareega xawaaraha sare leh, agabka qallafsan iyo kuwa fiican waa la kala saaraa. Alaabta wanaagsan ee waafaqsan shuruudaha cabbirka waxay galaan kala-soocida duufaanta iyo boodhka ururiyaha iyada oo la kala saarayo taayirrada, halka walxaha aan fiicneyn ay hoos ugu dhacaan qolka wax lagu shiido si joogto ah.

-

Taxanaha HS Pneumatic Jet Mill

Taxanaha HS pneumatic Mill waa qalab qaadanaya socodka hawo-xawaaraha sare ilaa walxo qallalan.

-

Taxanaha HPD Pneumatic Jet Mill

Alaabta waxaa lagu keenaa qolka burburinta iyada oo hawo cadaadisku saaran tahay iyada oo loo sii marayo jet wax-quudinta. Hawada ciriiriga ah waxay u qaybisaa dhowr diyaaradood oo hawo si isku mid ah si ay u sii daayaan hawada transonic, taas oo ka dhigaysa qulqul xoog leh qolka warshadda si ay ugu khasabto qayb ka mid ah walxaha inay isku dhacaan oo xoqaan.

-

Taxanaha HJ Mechanical Super Fine Pulverizer

Qalabku waa nooc cusub oo wax shiida. Waxay leedahay saxan firfircoon iyo saxan taagan. Maaddada waxaa lagu shiiday saamaynta, is-jiidhka iyo goynta xoogagga saxanka taagan iyadoo la raacayo xawaaraha sare ee wareega ee saxanka firfircoon. Cadaadiska xun marka la eego, budada u qalantaa waxay gashaa aagga kala soocida waxaana soo aruuriya aruuriyaha halka walxaha aan fiicneyn ay ku soo laabanayaan shiidi dheeraad ah.

-

Kubbada Mill & Khadka Soo saarista Kala Soocida Horizontal

Geedi socodka oo dhan ee tiknoolijiyada waxay hubisaa in sii daynta boodhka uu ka hooseeyo 40 mg / m3 iyo 20 mg / m3 ka dib wax soo saarka, iyada oo la qaadanayo isku dhafka boodhka ururiyaha, fannaanka qabyada ah iyo nidaamka gudbinta pneumatic, xakamaynta adag ee dhibic kasta oo boodh ah. , iyo isticmaalka walxaha shaandhada tayada sare leh. Qalabku wuxuu ka hortagi karaa daadinta boodhka wuxuuna ka dhigayaa dhammaan habka tignoolajiyada mid xun oo nadiif ah.

-

Kubbada Mill & Khadka Soo saarista Kala Soocida Toosan

Codsiga

Qalabka jilicsan: calcite, marble, limestone, barite, gypsum, slag iwm.

Waxyaabaha adag: quartz, felspa, carborundum, corundum, sibidhka ganaaxa iwm.