Birta birta, sida qashinka ugu dambeeya ee ay soo saarto birta dhalaalaysa, waxay ka kooban tahay walxo bir ah oo sarreeya.Sababtoo ah cufnaanta sare iyo cufnaanta sare ee sare, lama faafin karo oo laga faa'iidaysan karo warshadaha dhismaha.Khayraadka birta ah ee qaaliga ah si fiican looma soo kaban, taasoo keentay xaddi qashin ah.Birta birta ah waa in dib loo warshadeeyaa oo dib loo isticmaalaa iyada oo loo marayo hab gaar ah oo kala soocida birta, oo ay buuxiso shuruudaha darajada birta budada ah ee looga baahan yahay walxaha ay ku jirto birta ee dhalada foornada, si birta dib loo warshadeeyo.Si fiican ayaa loogu isticmaali karaa dhismaha.

Waqtigan xaadirka ah, habka kala-soocidda magnetic qaarkood waa hab macquul ah, waana lagama maarmaan in la doorto qalab ku habboon si loo gaaro kala-soocidda birta iyo soo kabashada hufan.Birta birta ah ayaa dhulka lagu sifeeyaa si ay u garato kala qaybsanaanteeda, ka dibna iyada oo loo marayo hawada qallalan ee magnetka qallalan ee macdanta budada ah, macdanta quudinta, xoogga iyo dabada ayaa loo kala horreeyaa, wadarta guud ee darajada birta waa la falanqeeyaa oo la falanqeeyaa si loo helo habka iyo qalabka ugu fiican. xuduudaha.Bixi taageero farsamo oo ku habboon wax soo saarka dhabta ah.

Guryaha birta birta

Steel slag waa qashinka qashinka ah ee ay soo saarto isticmaalka lime-magnesium-sare, lime firfircoon iyo qalab kale oo kaabayaal ah oo loogu talagalay wasakhaynta iyo oksijiinta afuufka habka birta samaynta, sidaa daraadeed waxa ku jira oksaydh bir ah oo aad u sarreeya, guud ahaan 20% -40%, iyo FeO content. wuu ka badan yahay Fe2O3, kan hore guud ahaan waa 15%-25%, halka kan dambe uu yahay 5%-15%, labaduba waxay muujinayaan magnetism daciif ah.

Qalabka tijaabada

Qalabka imtixaanku wuxuu qaataa FX0665 budada budada hawada qalalan ee kala-soocida magnetic ee Shirkadda Huate, kaas oo inta badan loo isticmaalo xulashada hore ee magnetite ka hor inta aan la shiidi ama soo saarista xooga u qalma ee magnetite budada ah.

Kala-soocida birta ee hawada qallalan ee budada ah

Mabda'a shaqada

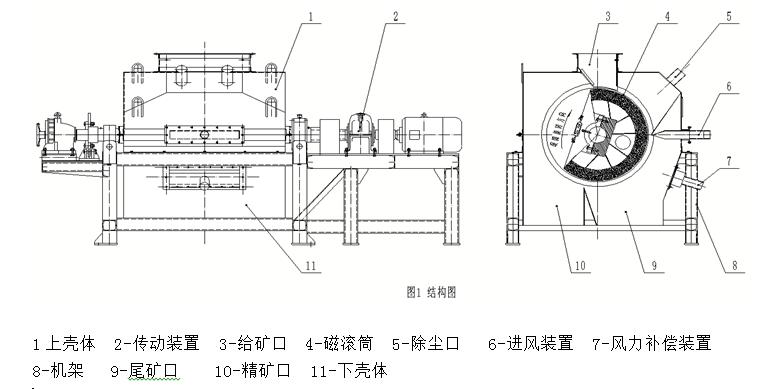

qolof sare 2.gudbin 3.Feed Hole 4.Magnetic roller 5.booska ka baxa 6.Aalada hawada qaadata 7.qalabka magdhowga dabaysha 8.Frame 9.Dabo dabo furan 10.Furitaanka xooga saara

qolof hoose

Mabda'a shaqada ee budada macdanta hawada qalalan kala-soocida magnetka ayaa lagu muujiyay shaxanka.Macdanta waxaa lagu quudiyaa dusha sare ee durbaanka magnetic iyada oo loo marayo dekedda quudinta macdanta 3, iyo macdanta magnetic waxaa lagu dhajiyaa dusha sare ee durbaanka magnetic 4 ee hoos yimaada ficilka xoogga magnetic, waxayna ku wareegaan durbaanka magnetic 4. Inta lagu jiro wakhtigan habka, macdanta dusha sare ee durbaanka magnetic 4 waxaa lagu sakhiray ficilka isku dhafan ee garaaca magnetic of duudduuban-xagalka weyn iyo tiirarka magnetic multi-ciir, qalabka walaaqaya magnetic, qalabka gelitaanka hawada 6 iyo dekedda saarista boodhka. 5, si wasakhda ku jirta macdanta iyo noolaha isku xidhan ee liita ay meesha ka saaraan.Sidaas awgeed, heerka fiirsashada ayaa la hagaajiyaa.Ka dib markii macdanta la xushay loo rogo aagga aan magnetka ahayn ee leh durbaanka magnetic 4, waxay ku hodmaan dekedda xoogga leh ee 9 ee hoos yimaada ficilka cuf-jiidka, xoogga centrifugal iyo qalabka dejinta si ay u noqdaan kuwo xoog leh.Macdanta aan magnetka ahayn ama jirka isku xiran ee caatada ah ayaa laga saaray afka dabada 8 ee hoos yimaada ficilka cufisjiidka iyo xoogga centrifugal, oo noqda dabo ama macdan dhexdhexaad ah.

Hal-abuurnimada iyo tignoolajiyada muhiimka ah ee budada budada hawada qallalan ee kala-soocida

1.Fadiyaha gariiraya waxaa loo isticmaalaa quudinta, iyo xuduudaha quudiyaha waa la hagaajin karaa si loo gaaro quudin isku mid ah;

2.Nidaamka magnetic wuxuu qaataa tiirar badan, xagal duuban oo waaweyn (ilaa 200-260 digrii), naqshadaynta xoogga sare ee goobta (3000-6000Gs), iyo qaab dhismeedka nidaamka magnetic waa la bedeli karaa iyadoo loo eegayo sifooyinka macdanta si loo gaaro tilmaamayaasha faa'iidada macquulka ah ;

3.Xawaaraha tooska ah ee dhululubada waxaa lagu hagaajiyaa gudaha 1-20m / s, iyo xawaaraha saxda ah ee ku habboon ayaa loo dooran karaa iyadoo loo eegayo dabeecadda macdanta;dhululubada waxa uu ka samaysan yahay walxo aan bir ahayn waxana lagu qalabeeyaa qalab kicinta birlabeedka si kor loogu qaado heerka xooga saarida;

4.Waxay leedahay qaab-dhismeedka mindida hawada gaarka ah, qalabka magdhowga dabaysha iyo qalabka boodhka ka saarida (xaddiga ku habboon ayaa loo dooran karaa iyadoo loo eegayo shuruudaha dabeecadda iyo tusmooyinka macdanta);dusha sare ee dhululubada waxaa la siiyaa qalab dejin, kaas oo ogaan kara dheecaanka nadiifka ah ee xoogga;

The FX budada ore hawada qalalan magnetka inta badan ka kooban yahay qalabka gudbinta, durbaan kala soocida magnetic, qalab afuufo, qalab ka saara boodhka qabyo ah induced, qalab ururinta sedimentation, iwm. Awooda goobta magnetic ee durbaan kala soocida magnetic waa 3500Gs ., xoog magnetic, xoog centrifugal wareeg ah, iwm, gaari karaan pre-doorashada qalalan of 0-5mm size magnetite ama si weyn u wanaajiso darajada magnetite budada ganaax.Saamaynta ugu weyn waa sida soo socota:

A. Fasalka la doortay ee 0-5mm magnetite waxa laga kordhin karaa ilaa 10% ilaa in ka badan 40%.Waxaa loo isticmaali karaa sidii hore loo tuuri lahaa ka hor inta aan la shiidi, taas oo si weyn u wanaajin karta fasalka gelitaanka iyo hagaajinta waxtarka mashiinka.

B.Darajada la xushay ee -74um iyo -45um magnetite-grained fine-grained waxaa laga kordhin karaa ilaa 10% ilaa in ka badan 60%, iyo xoogga u qalma waxaa si toos ah loo heli karaa by xulashada qalalan.

Habka tijaabada iyo falanqaynta.

① Falanqaynta walxaha caadiga ah iyo ogaanshaha walxaha birta ah.

② Diyaarinta iyo nadiifinta macdanaha aan biraha ahayn sida Ingiriisida, dhagax dheer, fluorite, fluorite, kaolinite, bauxite, caleen wax, baryrite, iwm.

③Ka faa'iidaysiga biraha madow sida birta, titanium, manganese, chromium iyo vanadium.

④ Ka faa'iidaysiga macdanta macdanta magnetic daciifka ah sida tungsten madow, tantalum niobium ore, rummaan, gaaska korantada, iyo daruur madow.

⑤ Ka faa'iidaysiga guud ee agabka sare sida dabada kala duwan iyo dhar dhalada.

⑥ Waxaa jira ore-magnetic, culus iyo sabbeynta isku darka faa'iidooyinka biraha ferrous.

⑦ Kala soocida dareenka caqliga leh ee macdanaha macdanaha ah iyo kuwa aan birta ahayn.

⑧ Imtixaan doorasho joogto ah oo semi-warshadeed ah.

⑨ Qalabaynta budada Ultrafine sida burburinta walxaha, shiididda kubbadda iyo kala-soocidda.

⑩ Mashaariicda furaha EPC sida burburinta, xulashada hore, shiidi, kala soocida magnetic (culus, sabbeynta), raft qalalan, iwm.

Waqtiga boostada: Mar-14-2022