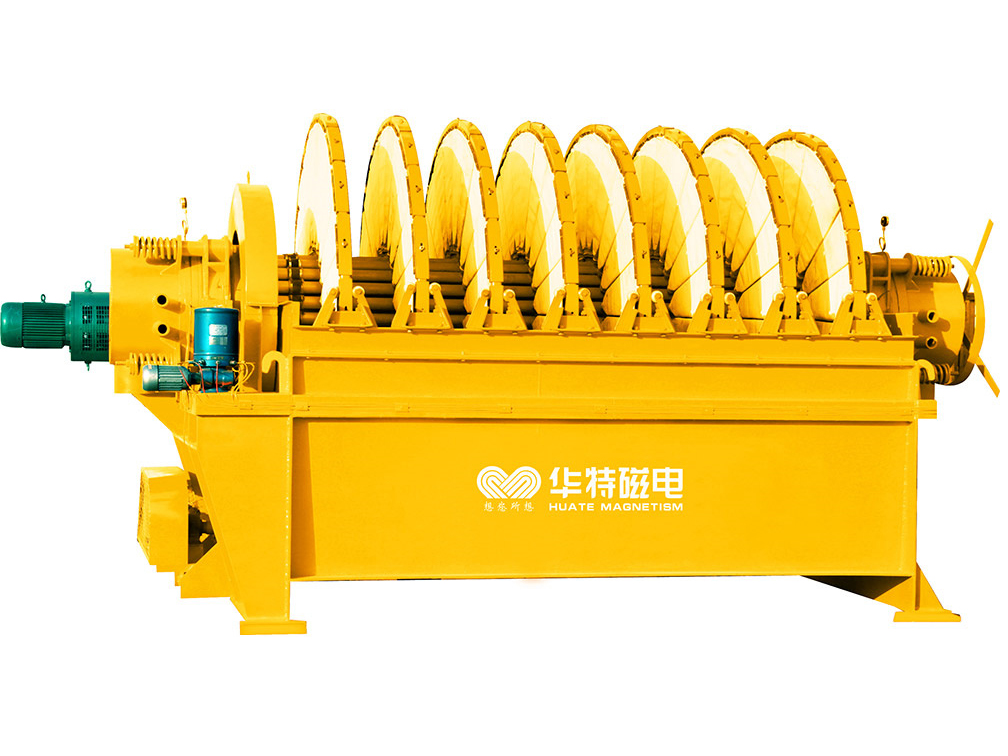

Budada Qalalan ee Electro Magnetic Bir ka saara

Lagu dabaqi karo

Waxaa inta badan loo isticmaalaa in laga saaro walxaha magnetka ah ee alaabta batteriga, ceramics, carbon black, graphite, retardants ololka, cuntada, budada dhalaalka naadirka ah ee dhulka, alaabta sawir-voltaic, pigments iyo alaabta kale.

mabda'a shaqada

Marka gariiradda kicinta la tamarsiiyo, goob birlab xoog leh ayaa ka abuurma bartamaha gariiradda, taas oo kicisa matrix-ka magnetka ee dhululubada kala-soocidda si ay u abuurto goob birlabeed sare leh. Marka maaddadu dhex marto, maaddada magnetic waxaa nuugaya matrixka magnetic, si markaa loo helo feejignaan sare oo nadiif ah; Ka dib marka la shaqeeyo wakhti wakhti ah, marka awoodda xayeysiinta ee matrixku ay gaadho saturation, quudinta waa la joojiyaa, qaybinta qaybinta si toos ah Waxay u leexataa dekedda dheecaanka birta, iyo gariiradda kicinta ayaa dami si ay u demagnetize matrixka, isla markaa, matoorka gariirku wuxuu kordhiyaa baaxadda, iyo walxaha birlabku si habsami leh ayaa loo sii daayaa. Habka kala-soocidda oo dhan si toos ah ayaa loogu socodsiin karaa iyada oo loo marayo goobaha barnaamijka.

Qiyaasaha Farsamada

| Qaabka | Xaaladda kulaylka xoogga bannaan ee bannaan | Xaaladda kulaylka xoogga goobta shaqada | Kala soocida qolka dhexroorka | Awooda habaynta tixraaca ciid | Awooda habaynta tixraaca lithium | Awooda habaynta tixraaca garaafka |

Miisaanka |

Awood xiiso leh |

Dhererka qalabka |

| Gauss | Gauss | mm | kg/saacaddii | kg/saacaddii | kg/saacaddii | kg | kW | mm | |

| HCT 100-3500 | 3500 | 14000 | 100 | 370 | 110 | 100 | 1040 | 5.0 | 1750kii |

| HCT 150-3500 |

3500 |

14000 | 150 | 850 | 255 | 230 | 2465 | 6.8 | 1800 |

| HCT 250-3500 | 250 | 1850kii | 555 | 500 | 3100 | 11 | 1940kii | ||

| HCT 300-3500 | 300 | 3200 | 960 | 865 | 4150 | 12.5 | 1960kii | ||

| HCT 350-3500 | 350 | 4350 | 1300 | 1170 | 4980 | 15 | 2180 | ||

| HCT 400-3500 | 400 | 5600 | 1700 | 1500 | 5670 | 18 | 2310 | ||

| HCT 100-5000 |

5000 |

20000 | 100 | 370 | 110 | 100 | 1460 | 10 | 1750kii |

| HCT 150-5000 | 150 | 850 | 255 | 230 | 2630 | 13 | 1800 | ||

| HCT 250-5000 | 250 | 1850kii | 555 | 500 | 3350 | 16.5 | 1940kii | ||

| HCT 300-5000 | 300 | 3200 | 960 | 865 | 4500 | 26 | 1960kii | ||

| HCT 350-5000 | 350 | 4350 | 1300 | 1170 | 5860 | 35 | 2180 | ||

| HCT 400-5000 | 400 | 5600 | 1700 | 1500 | 6600 | 42 | 2310 |

Tilmaamaha Farsamada

◆ Falanqaynta curiyaha xaddidan ee magnet-ka ee tignoolajiyada jilitaanka kumbuyuutarku waxay qiyaas ahaan xisaabin kartaa qaybinta iyo cabbirka goobta magnetic, iyada oo hubinaysa naqshadda macquulka ah ee wareegga magnetka.

◆ Gariiradda xiisaha badan ayaa ah qaybta udub-dhexaadka u ah mishiinka oo dhan, kaas oo siinaya goob magnetic xasiloon qalabka. Si loo hubiyo qaboojinta degdega ah ee kulaylka ka dhalanaya gariiradda, gariiraddu waxay qabataa kanaalka saliidda qaab dhismeedka saddex-geesoodka ah, kaas oo labanlaabaya aagga kuleylka kulaylka isla markaana ku habboon kuleylka kuleylka ee saliidda beddelka.

◆ Qaadashada habka qaboojinta isku dhafan ee saliidda-biyaha, oo isticmaal bamka saliidda qulqulaya si aad u dedejiso wareegga saliidda kulul si aad dhaqso uga saarto kulaylka, iyo kor u kaca heerkulka gariirku waa yar yahay si loo hubiyo in gariiraddu ay si la isku halleyn karo ugu shaqeyn karto heerkul hoose. Guryaha gariiradda ayaa qaata qaab-dhismeed si buuxda u xidhan, kaas oo aan qoyaanka ilaalinayn, boodhka-celin iyo daxalka-ilaalin, oo la qabsan kara deegaanno adag oo kala duwan.

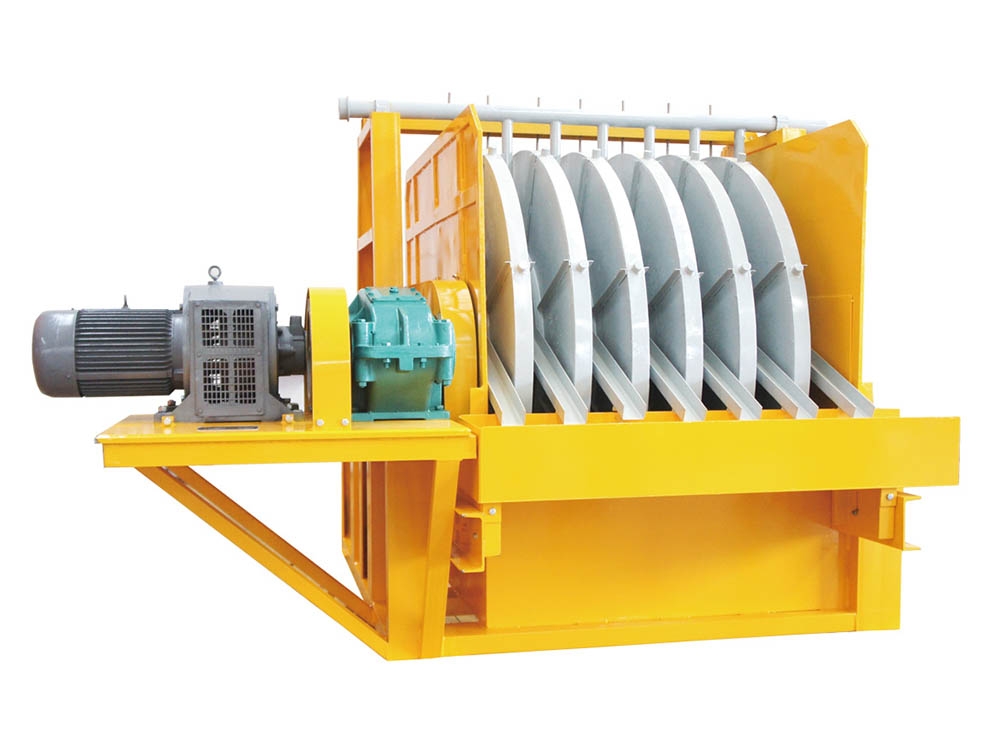

◆ Matoorka gariirku wuxuu khuseeyaa gariir-sare oo sarreeya, gariir hoose oo hooseeya ee jihada toosan ee dhululubada walxaha gariiraya, kaas oo si wax ku ool ah u wanaajin kara awoodda gudbinta ee walxaha aan magnetic, ka hortagga xiritaanka walxaha, iyo kordhinta awoodda wax soo saarka; markaad soo dejinayso birta, kordhi baaxadda oo ka soo deji birta si nadiif ah.

◆ Nadaamka kantaroolku waxa uu ku qalabaysan yahay tignoolajiyada casriga ah ee man-machine interface, waxana uu kula xidhiidhaa maamulaha barnaamijka wakhtiga dhabta ah iyada oo loo marayo Host Link baska ama fiilada shabakada. Iyada oo la adeegsanayo is-dhexgalka man-mashiinka, ka shaqee oo la soco qalabka, oo si firfircoon u darso macluumaadka khaladka ah.

◆ Uruurinta xogta goobta iyada oo loo marayo dareemayaal iyo gudbiyeyaal, oo isticmaal aragtida kontoroolka sare ee PID (constant current) iyadoo loo eegayo cabbirrada farsamaynta macdanta ee uu bixiyo isticmaaluhu. Iyadoo aan loo eegin haddii qalabku ku jiro xaalad kulul ama qabow, nidaamka xakamaynta ayaa si dhakhso ah u gaari kara xoogga goobta kicinta ee la qiimeeyay. Waxay xallisaa dhibaatooyinka hore ee hoos u dhaca xoogga magnetic iyo kor u kaca iyo xawaaraha demagnetization marka qalabku ku socdo xaalad kulul.

◆ Matrix-ku wuxuu ka samaysan yahay SUS430 bir aan fiicneyn oo bir ah oo bir ah. Marka loo eego cabbirka maaddada, waxay noqon kartaa qaab ulo, go'yaal jiingado iyo meshes. Qaybo badan oo warbaahin ah ayaa la dhigaa si kale, si alaabta si buuxda loo kala saarobirtana si nadiif ah ayaa looga saari karaa.