Aagga kala-soocidda ee xoogga goobta dhexdhexaadka ah ee semi-magnetic is-dejinta dabada dib u soo kabashada waxay leedahay aag birlab ah oo xooggan, aag birlab dhexdhexaad ah iyo aag birlab ah oo daciif ah. Polarity ee tiirarka birlabku waxay si beddel ah u sameeyaan nidaam magnetic anular semi-wareeg ah. Qayb ka mid ah qolofka ayaa lagu dhex milmay saxarka, qaybaha magnetic ee saxarka ayaa si joogto ah loogu dhajiyaa habka wareegga joogtada ah. Qalabka birlabeedka ayaa si joogto ah loo dhaqaa. Ma jiro goob birlabeed ah oo ku taal qaybta sare ee midig ee nidaamka magnetic semi-ring. Walxaha waxaa lagu sii daayaa haanta xoogga leh.

Astaamaha

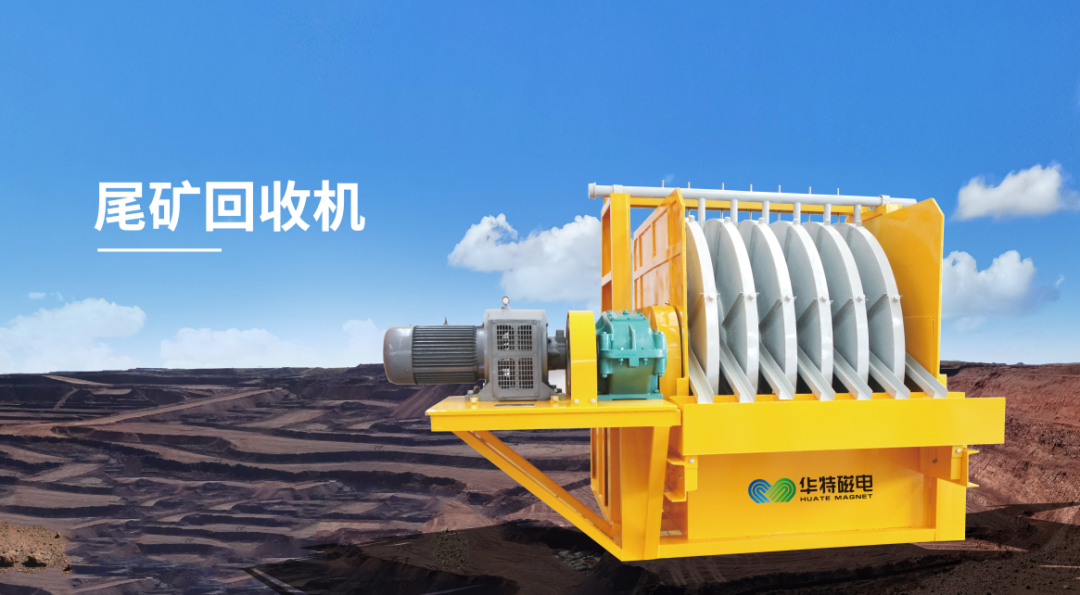

Taxanaha YCBW ee awoodda dhexdhexaadka ah ee semi-magnetic is-dejinta dabada kabashada mashiinka soo kabashada ee ay soo saartay Shirkadda Huate waxay leedahay sifooyin xirid wanaagsan, isku halaynta sare iyo nolosha adeeg dheer.

Aagga birlabeedka, tirooyin badan oo lammaane bir magnetic ah oo leh tiirar iska soo horjeeda ayaa si kale loo habeeyaa. Inta lagu jiro wareegga, maaddada magnetic si joogto ah ayaa loogu rogaa saxanka ururinta iyo biyaha, la dhaqo oo la nadiifiyo, si qalabka magnetic soo kabsado uu u yeesho nadiif sare iyo saameyn soo kabasho oo wanaagsan.

Aag birlabeedka daciifka ah ayaa la dhigay inta u dhaxaysa aagga magnetic field iyo aagga aan magnetka ahayn ee saxanka magnetic. Marka maaddada birlabku ay gasho aagga aan magnet-ka ahayn, waxay ka gudubtaa aagga kala-guurka magnetic daciifka ah, iyo aagga xayeysiiska ee aagga magnetic daciifka ah ayaa si tartiib tartiib ah hoos ugu dhacaya. leexleexiyaha u janjeera wuxuu kaloo ka ilaaliyaa walxaha magnetic inay dib u socdaan waxayna awood u yeelaan dheecaan degdeg ah oo hoos yimaada ficilka cufisjiidka iyo nadiifinta biyaha.

Habka gudbinta nooca suunka ayaa ka fogaanaya khatarta qarsoon ee gubashada matoorka sababtoo ah nidaamka magnetic.

Matoorka xakameynaya xawaaraha korantada ayaa la qaatay, kaas oo fudud in lagu shaqeeyo oo lagu shaqeyn karo xirfadlayaal la'aan, kharashka dayactirkuna waa yar yahay.

Kala duwanaanshaha codsiga iyo saamaynta

Taxanaha YCBW Mashiinka soo kabashada dabada ee taxanaha dhexdhexaadka ah ee semi-magnetic is-loading dabada soo kabashada oo ay soo saartay Huate waxa ay soo kaban kartaa macdanta birlabeed dhexdhexaadka ah ee slurry.

Isku-dubarid Anshan Iron iyo Steel ayaa doortay 8 qaybood oo YCBW-15-8 ah xoogga goobta dhexe ee semi-magnetic is-dejinta dabada mashiinnada soo kabashada dabada. Saamaynta soo kabashada waa sida soo socota:

Mashiinka soo kabashada dabada xooggiisa dhexdhexaadka ah ee semi-magnetic is-dejinta: awoodda farsamaynta saxarka waa 700-800m³/h, iyo macdanta birta magnetic ee macdanta waa 2.3-2.5%. Ka dib markii lagu soo celiyay mashiinka soo kabashada dabada, maadada birta magnetic ee dabada ayaa hoos loo dhigaa 0.5-0.7%, saameynta soo kabashada waa mid cajiib ah.

Baaxadda adeegyada farsamada ee Huate Mineral Processing Engineering Institute Design

① Falanqaynta walxaha caadiga ah iyo ogaanshaha walxaha birta ah.

②saarista iyo nadiifinta macdanta aan biraha ahayn sida quartz, feldspar, kaolin, bauxite, spodumene iyo pyrophyllite.

③Iron, titanium, manganese, chromium, vanadium iyo ka faa'iidaysiga biraha kale ee ferrous.

Ka faa'iidaysiga macdanta macdanta magnetic daciifka ah sida dhulka naadirka ah, wolframite, tantalum-niobium, garnet iyo tourmaline.

⑤ Ka faa'iidaysiga guud ee agabka sare sida dabo iyo dabo kala duwan.

⑥ Macdanta bir ah ee aan birta ahayn ee kala-saarista

⑦Madano madow, aan bir lahayn iyo macdan aan bir ahayn oo kala soocida dareemayaasha caqliga.

⑧ Qalabaynta budada Ultrafine sida burburinta walxaha, kubad-shiididda iyo darajaynta.

⑨ Imtixaan xul ah oo warshadaysan.

⑩ Mashaariicda furaha EPC sida burburinta, xulashada hore, shiidi, kala soocida magnetic (culus, sabbeynta), iyo dheecaanka qallalan ee dhirta warshadaynta macdanta.

Waqtiga boostada: Mar-28-2022